The Importance of Surface Finishing

Surface finishing is a crucial step in the manufacturing process that involves treating the exterior of a product to improve its appearance and durability. It plays a significant role in enhancing the overall quality of the product and providing protection against corrosion and wear.

The Benefits of Powder Coating

Powder coating is a popular surface finishing technique that involves applying a dry powder to a product and then curing it to create a seamless and durable finish. This method provides several advantages, including resistance to chipping, scratching, and fading, making it an ideal choice for a wide range of applications.

Types of Powder Coating Options

There are various types of powder coating options available, each with its unique characteristics and benefits. Some common options include thermoset powders, thermoplastic powders, metallic powders, and clear coats, allowing manufacturers to choose the best option based on their specific requirements.

Surface Finishing Techniques

Surface finishing techniques vary depending on the material and desired finish. Some popular techniques include abrasive blasting, electroplating, anodizing, and polishing, each offering different levels of durability, aesthetics, and corrosion resistance.

Environmental Benefits of Powder Coating

Powder coating is known for its environmental friendliness compared to traditional liquid coatings. It produces less waste, emits fewer volatile organic compounds (VOCs), and can be recycled, making it a sustainable choice for eco-conscious manufacturers.

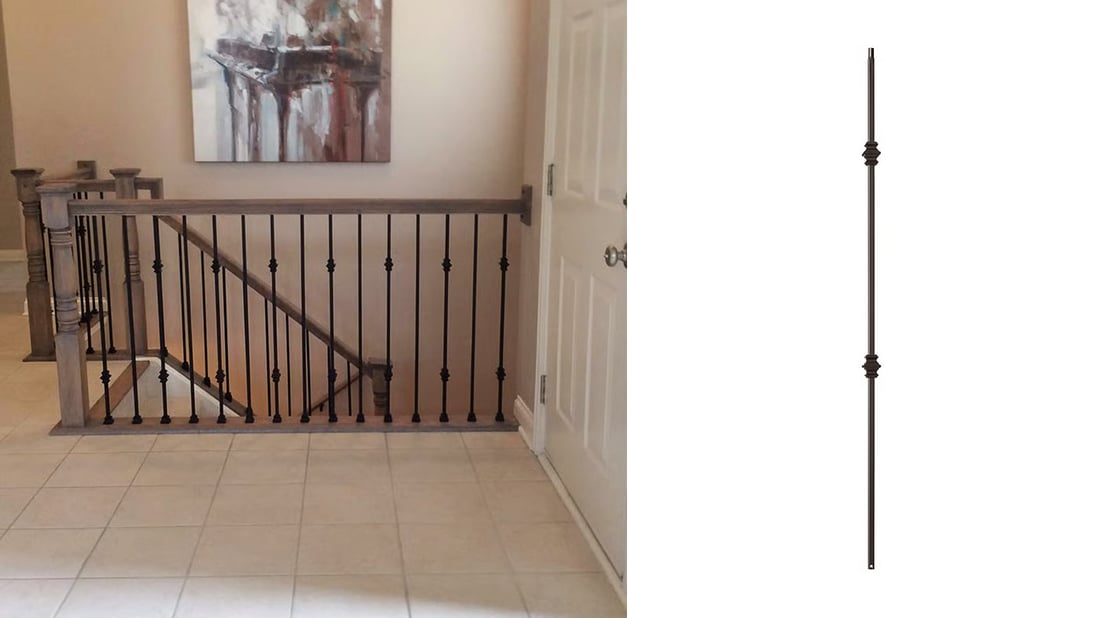

Customization Options for Surface Finishing

surface finishing and powder coating options provide a high level of customization, allowing manufacturers to choose from a wide range of colors, textures, and finishes to meet their specific design requirements. This versatility makes it a versatile choice for a variety of industries.

Cost Considerations in Surface Finishing

When selecting surface finishing and powder coating options, cost is a significant factor to consider. The overall cost may vary depending on factors such as the size of the project, the complexity of the finish, and the specific materials used. However, the long-term benefits of durability and protection often outweigh the initial investment.

Quality Control in Surface Finishing

Quality control is essential in surface finishing to ensure that the finished product meets the required standards for appearance, functionality, and durability. Inspecting the product at various stages of the finishing process is crucial to identify any defects or imperfections that need to be addressed.

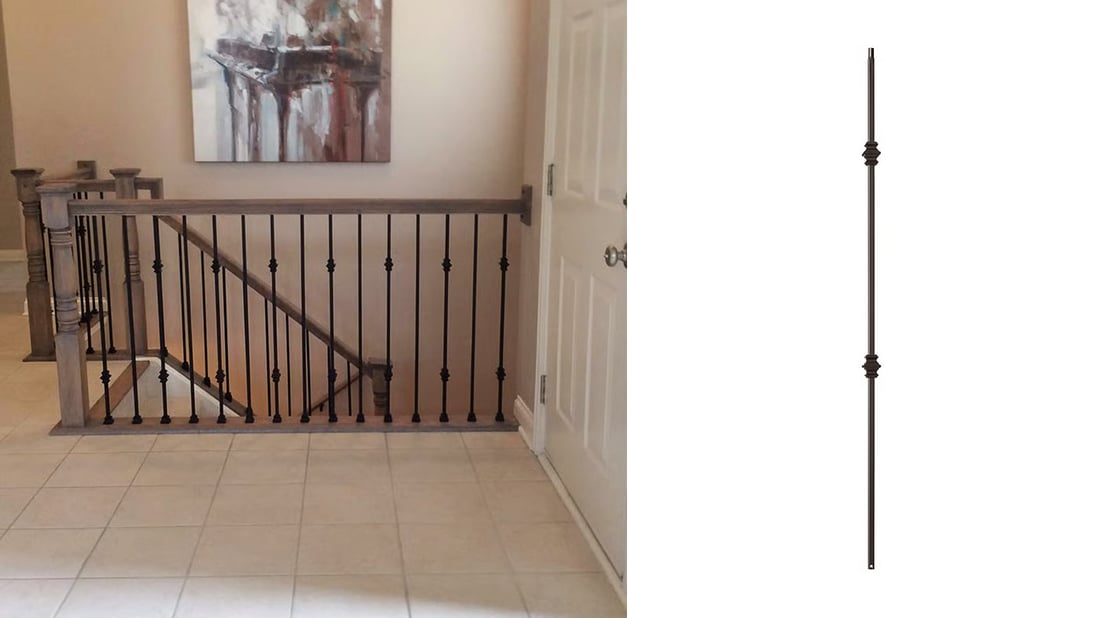

Industry Applications of Powder Coating

Powder coating is widely used across various industries, including automotive, aerospace, appliances, furniture, and architecture. Its versatility, durability, and ability to create a flawless finish make it a popular choice for manufacturers looking to enhance the aesthetics and longevity of their products.

Future Trends in Surface Finishing

As technology continues to advance, the future of surface finishing and powder coating options is likely to see further developments in terms of sustainability, customization, and efficiency. Innovations such as smart coatings, self-healing coatings, and nanotechnology are expected to revolutionize the industry and offer new possibilities for manufacturers.

Quote Inquiry

contact us