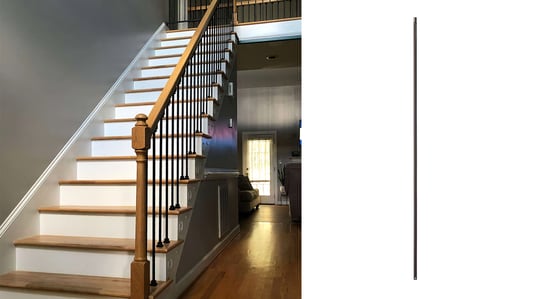

Benefits of Powder CoatingPowder coating is a popular method of applying a durable finish to metal surfaces. It creates a protective layer that is resistant to chipping, scratching, and fading, making it ideal for exterior applications such as iron balusters.White Powder-Coated SurfacesWhite powder coating is a versatile option for iron balusters, as it can complement a variety of design styles. It provides a clean and modern look that can brighten up any space, while still offering the durability needed for outdoor use.Resistance to CorrosionOne of the primary benefits of powder-coated surfaces on hollow iron balusters is their resistance to corrosion. The coating acts as a barrier that protects the metal beneath from rust and deterioration, extending the lifespan of the balusters.UV ResistanceWhite powder-coated surfaces on iron balusters are also UV resistant, meaning they can withstand prolonged exposure to sunlight without fading or discoloring. This makes them an excellent choice for outdoor applications where they will be exposed to the elements.Scratch and Chip ResistanceThe durable finish of powder-coated surfaces on hollow iron balusters makes them highly resistant to scratches and chips. This is particularly important for high-traffic areas or areas where the balusters may come into contact with other objects.Easy to Clean and MaintainMaintaining white powder-coated surfaces on iron balusters is easy and straightforward. Simply wiping them down with a mild detergent and water as needed will keep them looking fresh and new for years to come.Longevity of the FinishThe longevity of the finish on powder-coated surfaces is a significant advantage, as it means the balusters will maintain their aesthetic appeal for an extended period of time. This can save you time and money on maintenance and refinishing in the long run.Versatility in DesignWhite powder-coated surfaces on hollow iron balusters offer versatility in design, allowing them to be seamlessly integrated into various architectural styles. Whether you prefer a traditional, contemporary, or eclectic look, these balusters can adapt to your design aesthetic.Environmental FriendlinessPowder coating is an environmentally friendly finishing option, as it does not contain harmful solvents or emit volatile organic compounds (VOCs). Choosing powder-coated surfaces for your iron balusters is a sustainable choice that reduces your carbon footprint.Cost-EffectivenessWhile the initial cost of powder-coated iron balusters may be higher than other finishing options, the long-term cost-effectiveness of their durability and low maintenance requirements make them a wise investment. You can enjoy peace of mind knowing that your balusters will look great for years to come.Quote Inquirycontact us